-

-

Vadodara, Gujarat.

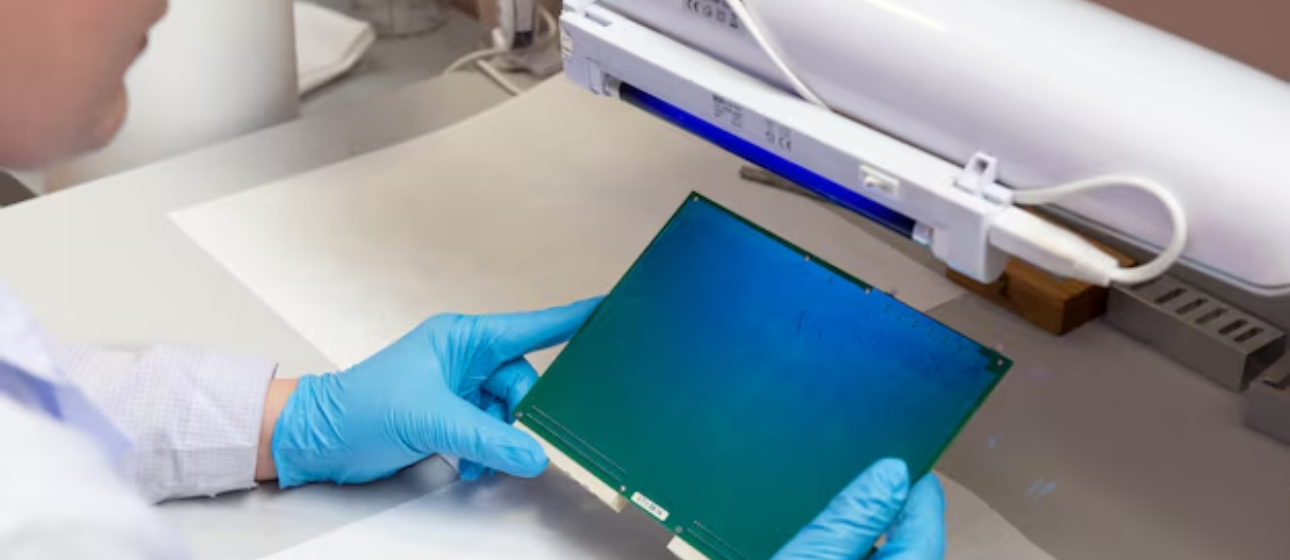

DOP/PAO HEPA Filter Integrity Test

Ensuring HEPA Filter Performance with DOP/PAO Integrity Testing

We offer comprehensive HEPA/ULPA filter integrity testing services for both the Pharmaceutical and Microelectronics industries, ensuring that filters meet stringent industry standards. Our testing is conducted in strict accordance with ISO 14644 to guarantee high-quality air filtration and compliance with regulatory requirements. We perform tests using Di-Octyl Phthalate (DOP) and Poly Alpha Olefin (PAO), depending on the specific needs of each client’s facility. These tests ensure that the filters function as intended, meeting the necessary standards and governing agency requirements for air cleanliness and contamination control.

Regular testing of filters, at least once or ideally twice annually, is essential for maintaining optimal performance and prolonging filter life. Our testing services not only ensure compliance but also help predict potential performance issues before they arise, minimizing downtime and maximizing efficiency. We provide detailed documentation and certification, which serves as both a compliance record and a preventive measure to ensure that filters continue to perform effectively and meet the highest standards.

-

Ensuring Air Quality Control

-

Regular Testing

-

Maximizing Efficiency

Maximizing Filter Efficiency with HEPA/ULPA Integrity Testing

Maximizing filter efficiency is crucial for maintaining cleanroom standards and ensuring optimal air quality. Our **HEPA/ULPA Filter Integrity Testing** service accurately evaluates filter performance using **DOP** and **PAO** methods to meet regulatory standards. Regular testing, at least annually or twice a year, helps identify potential issues early and prolongs the life of filters. By providing detailed documentation and certification, we ensure that your filters continue to perform at peak efficiency, safeguarding cleanroom environments and compliance with industry requirements.